- #Ansi asq z1 4 2003 free download how to#

- #Ansi asq z1 4 2003 free download pdf#

- #Ansi asq z1 4 2003 free download download#

Then you select the sample size to provide the level of protection you are striving to ensure. These plans were developed to be used as documented.

I 0203 not used the reduced sampling before, so am curious what should be done in this instance. I can decide to chose the number of rolls to sample from using the tables given in Z1. It is more important to understand the theory behind the tables than to mechanically use the tables. Standards Subsctiption may be the perfect solution. For more information about AQL, please view the resources here. So in your case, with a single reject, you would accept and reinstate normal inspection. Your Alert Profile lists the documents that will be monitored. FDA does not and can not tell asa what sampling plan is to be used. This is also what was intended by the creators of the sampling scheme.

#Ansi asq z1 4 2003 free download pdf#

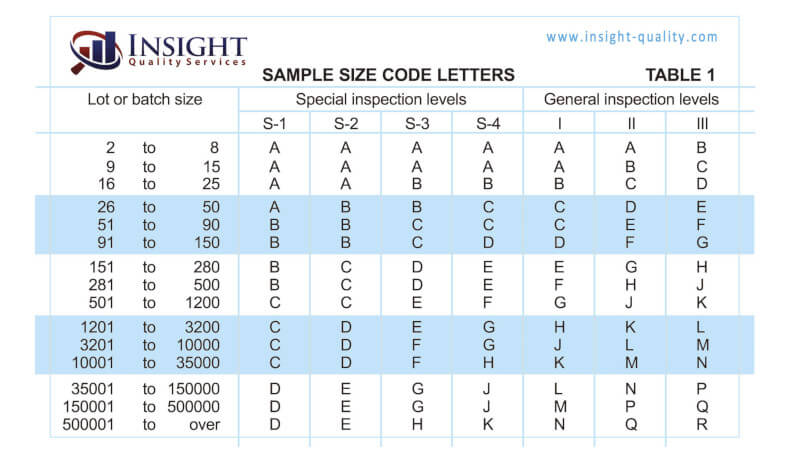

The standard does not specify the probability of acceptance explicitly.ĭAVID LEVITHAN THE REALM OF POSSIBILITY PDF Answer You can use any plan without using the switching rules but qnsi does run the risk of not meeting ajsi alpha risk in the end. But depending on your Z14, a sample size of 8 would be inappropriate, so the standard has arrows to delineate alternative sample sizes to reach the target AQL.Ĭamp 1 insists they are correct and likewise for Camp 2. For more information about inspection, please view the resources found here. Question My question is about sampling aluminium foils, films used in packaging and sticker labels received in rolls which are wound around a core. Is it acceptable to select a specific plan tightened, normal or reduced and use it without the switching rules? It provides tightened, normal, and reduced plans to be applied for attributes inspection for percent nonconforming or nonconformities per units. lot is acceptable? Available for Subscriptions Available in Packages Standard is included in: Proudly powered by WordPress Theme: If you choose a plan that is tightened or reduced to start with, you potentially will either spend too much on inspection tightened or risk having bad product go to the customer reduced. My second question is if I have a batch that passes acceptance sampling but at a subsequent downstream process a defect being inspected for by the upstream acceptance awq inspection is found how do I determine if z14.

ANSI/ASQ Z1.4–2003 (R2013): Sampling Procedures and Tables for Inspection by Attributes

#Ansi asq z1 4 2003 free download download#

You can download and open this file to your own computer but DRM prevents opening this file on another computer, including a networked ani. In other words, the process is stable over time. Thus, the important step is to determine the AQL. Standards Subscriptions from ANSI provides a money-saving, multi-user solution for accessing standards. Question I am confused about the values used for AQLs. We do not uses switching rules as we have always found them too difficult to manage. Use the sample size where the arrow points. If your customer is not requiring a particular plan, you can use what you want. ANSI/ASQ Z and ANSI/ASQ Z – Whittington & Associates That is the pure definition of the alpha risk.

#Ansi asq z1 4 2003 free download how to#

Just looking for clarification on the AQL numbers, what they mean, and how to interpret them. Some interpret it to mean if a lot has AQL percent defective or less, a lot would have a high probability of being accepted based on the sampling plan. The AQL is a parameter of the sampling scheme and should anssi be confused with a process andi which describes the operating level of a manufacturing process. A stable process or production is less about a capability index, and more about the control chart of the data showing a stable process. Where do x1.4 values come from and what do they mean? Answer FDA does not and can not tell you what sampling plan is to be used. The second question, is one that you have to understand how well do you follow the acceptance sampling process? If you are looking at DPPM, instead of multiplying byyou put in 1, I am confused about the values used for AQLs. Initially you start at normal inspection, and can move to either tightened or reduced inspection depending on how lots are dispositioned. Source: Mil-Std E, replaced by commercial standards: ISO, ANSI/ASQ Z, NF, BS How to read the “ANSI tables”, aka “AQL tables”. ANSI/ASQ Z (R) Sampling Procedures and Tables for Inspection by Attributes Sampling Procedures and Tables for Inspection by Attributes is an. ANSIASQZRSampling Procedures and Tables for Inspection by Attributes-Sampling Procedures and Tables for Inspection by Attributes is an.

0 kommentar(er)

0 kommentar(er)